In a world where robots are no longer just the stuff of sci-fi movies, integrating robotics into everyday operations is the new frontier. Picture this: a factory floor buzzing with machines that not only lift heavy loads but also crack jokes about your coffee addiction. Robotics integration isn’t just about efficiency; it’s about transforming the workplace into a space where humans and robots coexist in harmony—like a buddy cop movie but with fewer explosions.

As businesses race to adopt these technological marvels, they’re discovering that the right integration can boost productivity, reduce costs, and even make the office a little more fun. So, whether you’re a small startup or a giant corporation, it’s time to embrace the robots. After all, who wouldn’t want a tireless assistant that can also remind you to take a break? Welcome to the future of work, where the only thing standing between you and success is a well-placed robot arm.

Table of Contents

ToggleUnderstanding Robotics Integration

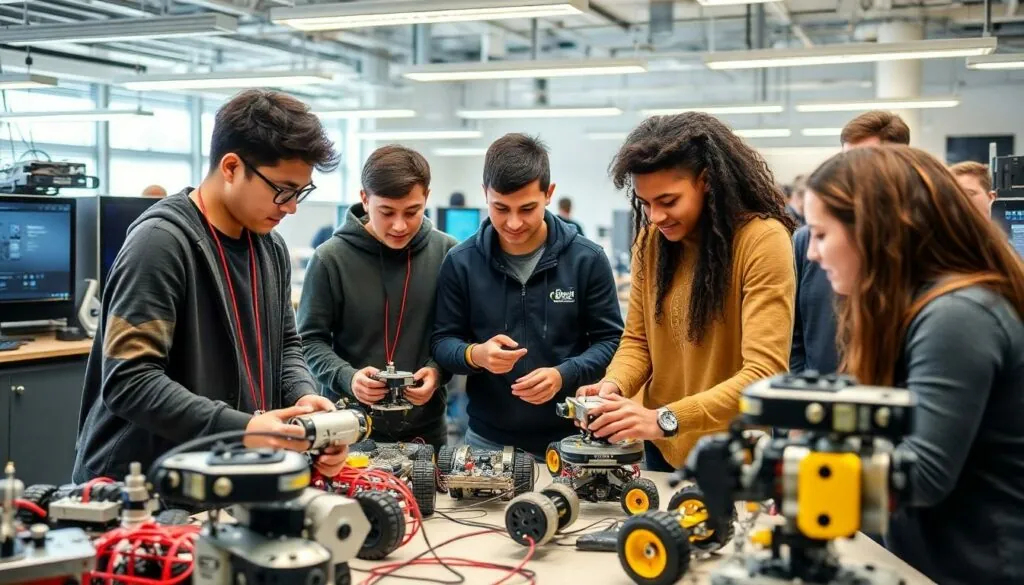

Robotics integration refers to the process of incorporating robotic systems into various business operations. This integration aims to streamline tasks, enhance efficiency, and create synergies between humans and machines.

Definition of Robotics Integration

Robotics integration encompasses the seamless connection of robots with existing systems and workflows. It involves not only hardware installations but also software adaptations that facilitate interaction with other technologies. This integration allows robots to perform specific tasks autonomously or alongside human workers, maximizing operational effectiveness.

Importance of Robotics Integration

Robotics integration significantly improves productivity across industries. By automating repetitive tasks, businesses free human workers to focus on more complex projects. Cost reductions also occur, stemming from enhanced efficiency and minimized errors. Additionally, the presence of robots can improve workplace safety by taking over hazardous tasks, thus reducing injury risks for employees. Embracing robotics integration leads to a more innovative and agile work environment, benefiting both employers and employees.

Applications of Robotics Integration

Robotics integration finds applications across various sectors, enhancing efficiency and productivity. Three industries leading the way include manufacturing, healthcare, and logistics.

Manufacturing Industry

In the manufacturing industry, robots play a pivotal role in automating repetitive tasks. Companies employ robotic arms for assembly line functions, improving speed and precision. They streamline processes like welding, painting, and material handling, reducing human error. Implementing robotics leads to lower production costs and increased output. Many manufacturers report significant gains in operational efficiency after integrating robotics. Advanced automation systems also allow for continuous operation, resulting in higher overall productivity.

Healthcare Sector

The healthcare sector benefits immensely from robotics integration. Robots assist in surgical procedures, allowing for greater precision and reduced recovery times. Hospitals use robotic systems for medication dispensing and patient care, enhancing service delivery. Additionally, robotic exoskeletons aid in physical rehabilitation, providing support for patients recovering from injuries. Integration of robotics in healthcare improves patient outcomes and maximizes staff productivity. By handling routine tasks, robots free healthcare professionals to focus on more critical responsibilities.

Logistics and Supply Chain

Logistics and supply chain operations leverage robotics for enhanced efficiency. Automated guided vehicles transport materials within warehouses, optimizing space utilization. Robots also take on inventory management, accurately tracking stock levels and locations. Employing robotics in fulfillment centers speeds up sorting and packing processes, ensuring faster delivery times. Companies that integrate robotics into their logistics experience notable reductions in operational costs and improved order accuracy. As e-commerce demand continues to rise, robotics integration in this sector remains crucial for maintaining competitiveness.

Benefits of Robotics Integration

Robotics integration offers numerous advantages that transform business operations significantly. Key benefits include increased efficiency, cost reduction, and enhanced accuracy.

Increased Efficiency

Increased efficiency is a primary benefit of robotics integration. Robots handle repetitive tasks quickly and consistently, freeing human workers to concentrate on complex projects. Through automation, businesses experience faster production cycles and improved throughput. Moreover, robotic systems operate 24/7 without fatigue, ensuring continuous workflow and production. This heightened efficiency leads to accelerated project completion and timely delivery of products and services.

Cost Reduction

Cost reduction follows closely behind increased efficiency in robotics integration. Automating tasks minimizes labor costs by decreasing the reliance on manual labor. Businesses also see reduced error rates, leading to fewer materials wasted on corrections. Furthermore, robots lower operational costs by optimizing production processes, which enhances resource utilization. Investing in robotics can yield substantial long-term savings, allowing companies to allocate resources more effectively across their operations.

Enhanced Accuracy

Enhanced accuracy is essential in industries like manufacturing and healthcare, where precision matters. Robotics integration elevates overall accuracy by consistently performing tasks without deviation. Robots come equipped with advanced sensors and algorithms, ensuring uniform quality in production. Consequently, this precision leads to improved product quality and greater customer satisfaction. In healthcare, enhanced accuracy during surgical procedures and medication dispensing proves critical for patient safety and outcomes.

Challenges in Robotics Integration

Robotics integration presents various challenges that organizations must navigate to realize the full potential of technology in the workplace.

Technical Hurdles

Technical hurdles often arise during the implementation of robotic systems. Compatibility issues between new robots and existing equipment can hinder operations. Ensuring seamless software integration becomes critical for maintaining efficient workflows. Shortage of skilled technicians further complicates the process, as these professionals are necessary for both installation and maintenance. System downtime caused by technical glitches can lead to significant productivity losses. Addressing these obstacles requires careful planning and a solid understanding of the technical landscape.

Workforce Adaptation

Workforce adaptation plays a crucial role in successful robotics integration. Employees may feel apprehensive about working alongside robots, fearing job displacement. Training programs designed to upskill workers can alleviate these concerns, fostering a collaborative environment. Clear communication about the benefits of robotics helps ease the transition. Engaging employees in the integration process enhances acceptance and encourages adaptability. Adapting the workforce is essential for maximizing the advantages of robotic technologies.

Integration with Existing Systems

Integration with existing systems poses another challenge for businesses. Organizations must assess their current infrastructure to determine compatibility with new robotic systems. Legacy systems can limit the effectiveness of automation efforts, making upgrades necessary. Loss of data during integration can disrupt operations if not handled carefully. Developing a phased implementation approach helps minimize risks associated with system integration. A strategic focus on comprehensive planning ensures that the transition is smooth and successful.

Future Trends in Robotics Integration

Robotics integration continues to evolve, showcasing innovative trends that shape the future of business operations.

Advancements in AI and Machine Learning

Enhanced artificial intelligence (AI) and machine learning technologies play a crucial role in robotics. These advancements enable robots to learn from data, adapt to changing environments and improve decision-making processes. Companies leverage these capabilities for predictive maintenance, which reduces operational downtime. Robots equipped with AI analyze patterns and optimize their performance, resulting in increased productivity. Machine learning algorithms enhance robots’ ability to interact with human workers, creating seamless collaboration and boosting overall workplace efficiency.

Collaborative Robots (Cobots)

Growth in the use of collaborative robots, or cobots, marks a significant trend in robotics integration. Cobots are designed to work alongside humans, promoting a safer work environment and enhancing productivity. These robots assist with tasks such as assembly, packaging, and sorting, enabling human workers to focus on complex projects. The flexibility of cobots allows businesses to deploy them in various sectors, from manufacturing to healthcare. As it becomes easier to program and operate cobots, more companies opt to integrate them into their workflows.

The Role of IoT in Robotics Integration

The Internet of Things (IoT) increasingly impacts robotics integration by connecting devices and facilitating data exchange. IoT enables robots to communicate with other machines and systems, enhancing coordination and efficiency in operations. Real-time data collection allows businesses to monitor performance and make informed decisions swiftly. As robots receive updates and feedback through IoT devices, they adapt and optimize their performance dynamically. This interconnectedness fosters a robust and agile work environment, further driving the potential of robotics integration across industries.

Robotics integration is reshaping the landscape of modern business. By seamlessly blending human and robotic efforts, companies can unlock unprecedented levels of efficiency and innovation. The advantages are clear: increased productivity, reduced costs, and enhanced workplace safety create an environment where both robots and humans thrive.

As organizations navigate the challenges of this integration, a proactive approach to training and communication can bridge the gap between technology and workforce. Embracing advancements in AI and IoT will further enhance the capabilities of robotics, ensuring businesses remain competitive in an ever-evolving market.

The future of work is bright with robotics as a partner. As these technologies continue to evolve, they promise to redefine how businesses operate, making the workplace not only more efficient but also more enjoyable for everyone involved.